Challenges at the seashore

In addition to soil conditioning, the convertible TBM of 11.5 m diameter had to modify its cutting wheel to work in the transition between rock and sand in the state of RJ

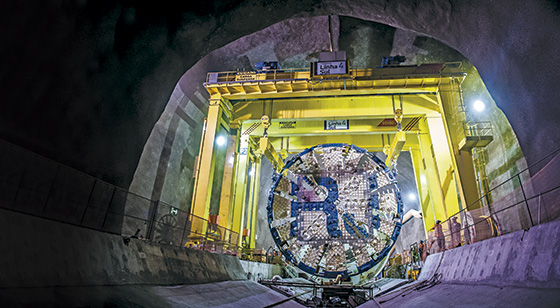

In the morning of February 25, a TBM with diameter of 11.5 m—equivalent to a four-floor building height—broke the walls of the station Nossa Senhora da Paz, in the district of Ipanema. Responsible by the excavation of the tunnels of the new Line 4 of Rio de Janeiro subway, the equipment has special features and represents a significant technologic advancement for underground works in the country.

Line 4 of the subway will be 16 km long with six new stations. It will transport 300,000 persons per day between Barra da Tijuca (West Zone) and Ipanema (South Zone). With total investment of R$ 8.79 billion, the project is among the largest projects of Latin America. It is also part of the preparation of the city carried out by the state government for the 2016 Olympic Games, when the line will be concluded.

Responsible by the connection between Ipanema and Gávea (5 km long), the Consortium Linha 4 Sul has already concluded the excavation of the station Nossa Senhora da Paz, including the tunnel that connects it with the Line 1 through the station General Osório. According to the time scheduling of the works, the TBM will conclude the section to the station Jardim de Alah in the middle of August, what corresponds to 50 percent of South section, and will reach the tunnels excavated from Barra da Tijuca (in the end of Leblon) till December, 2015.

CONVERTIBLE

Manufactured in Germany by Herrenknecht, the TBM, 120 m long and weighing 2700 t was specified and designed to work with the hard soil of Rio’s South Zone, composed by sections of rock, clay and coarse sand. To withstand this challenge, the consortium specified a “convertible” TBM that could work in three modes: opened, closed and transition.

In the definition of Alexandre Mahfuz, responsible by the operation of the TBM, the opened (non-pressurized) mode was used in areas of gneiss rock—hard and abrasive—

found in the initial (400 m) and final (1500 m) sections of the South Zone. In this type of excavation, the rock itself distributes soil pressure and ensures the stability of the excavation. But other challenges arrived and the team had to deal with fractured rocks and transition to sand soils, what made difficult to pass through these sections.

In the sand soils of Ipanema and Leblon, the TBM works in the EPB (Earth Pressure Balance) mode or closed mode. In this configuration, the front of the machine is pressurized to balance the pressures carried out by the soil and by the water blade, making feasible the excavation.

In the transitions from rock to sand and vice-versa, the TBM may work in the transition mode. The process uses compressed air to balance the pressures in the front, and injection of bentonite slurry that makes the soil waterproof and more cohesive. This solution is a mix of water and bentonite produced in the surface worksite and transported to the front of the TBM.

TRANSITION

As reports Mahfuz, the higher difficult when working with a convertible TBM is in the sections of soil transition. In these cases, the consortium carried out previous soil treatments in the sections of transition between rock and sand, injecting cement slurry in the underground before starting excavations, a process known as jet grouting.

In addition to soil conditioning, the cutting wheel was also modified, using discs designed to each type of soil. In rock excavation, the TBM works with 65 cutting disks with diameter spacing of 10 cm. The disks act with compression force on the rock to break it in small pieces that are removed by a conveyor to the tank of debris. In the sand sections, these cutters are changed by special scrapers and the machine passes to work in the closed mode.

When slurry is needed, the excavated material has to be carefully filtered and treated before it is reused or discarded. In this mode, different mixers, pumps and systems of injection and recycling of bentonite slurry are used.

Generally, when the TBM has lower diameters there is no space for the systems of closed and opened systems, and long stops are needed to change the conveyor by the auger and vice-versa. “But when we have a machine of larger dimensions, we may leave the systems preassembled, reducing the time of conversion”, complements Mahfuz.

For the engineer, even if convertible models are more practical, there are cases when a customized TBM tends to be more efficient if compared to a model to be used in more than one type of soil. In the section to be excavated in Rio de Janeiro, however, the machine for different soils showed some advantages. “It is a technologic alternative that we did not have twenty years ago, when excavation in this type of soil would be unfeasible”, ends him.

Av. Francisco Matarazzo, 404 Cj. 701/703 Água Branca - CEP 05001-000 São Paulo/SP

Telefone (11) 3662-4159

© Sobratema. A reprodução do conteúdo total ou parcial é autorizada, desde que citada a fonte. Política de privacidade